DTF Transfers By Size with Wholesale Prices

Buy more and save more with our selection of blank apparel or custom patches. Premium quality at competitive wholesale prices.

Customer Reviews

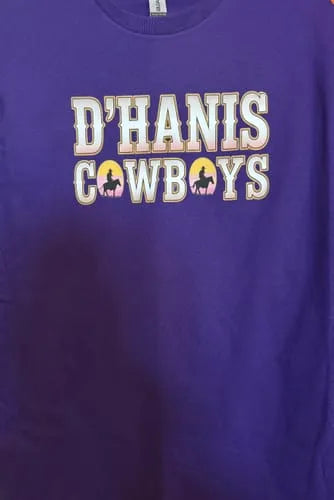

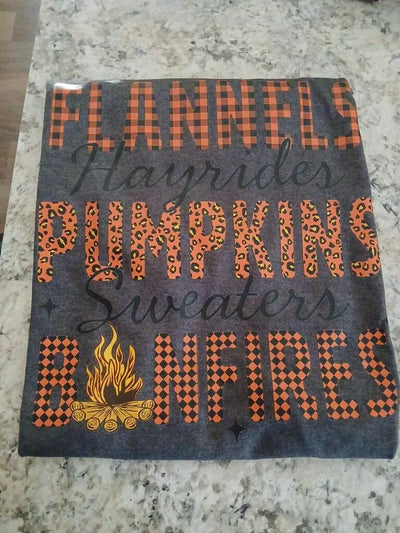

Real feedback on our DTF transfers, custom shirts, UV stickers and patches.

Sam is amazing she has the best customer service thanks so much for your help

Great product and fast shipping

Another set of amazing dtfs!! My only go to for my transfers.

Fast and easy to upload a design and get the logos.

The designs came off the gang sheet perfectly and were very vivid.

So easy to press

Great Quality, easy press, fast delivery

DTF Transfers By Size

Your Perfect Fit for Custom Designs

Welcome to ourDTF TransfersBy Size collection, where creativity meets precision. If you have a design ready to be brought to life, you've come to the right place. We understand that every project is unique, which is why we offer a variety of sizes to suit your specific needs. Whether you are printing for personal projects, small businesses, or large-scale orders, our DTF transfers are designed to provide the perfect fit for any application.

What Our Collection Offers

Our DTF transfersheetsare crafted using cutting-edge technology that ensures vibrant colors and intricate detail. With ourDTF transfers, you can expect high-quality prints that adhere seamlessly to a wide range of fabrics. From t-shirts to hoodies, our transfers are versatile enough to handle any fabric type, making them ideal for custom apparel. Each transfer is designed for easy application, allowing you to focus on your creativity rather than the technicalities of printing.

Versatile Use Cases for Every Project

The beauty of our DTF transfers lies in their versatility. Planning a family reunion and need matching t-shirts? Looking to create custom merchandise for your brand? Our collection has you covered. DTF transfers are perfect for various occasions, including sports events, corporate giveaways, and promotional items. With ourcustom DTF transferoptions, the possibilities are endless. You can create unique designs that reflect your style and message.

Durability and Quality You Can Trust

One of the standout features of our DTF technology is its durability. Unlike traditional transfer methods, DTF transfers offer superior resistance to cracking and fading, ensuring your prints look great wash after wash. Our DTF transfer printing process uses high-quality inks and materials, resulting in vibrant colors that stand the test of time. When you choose our products, you're not just getting a transfer; you're investing in quality that will keep your designs looking fresh for longer.

Customization Options to Suit Your Needs

At Ready2Transfer, we believe in giving you control over your designs. Our DTF transfer size chart helps you select the perfect dimensions for your project, ensuring a flawless application every time. Whether you need a small logo or a large graphic, our range of sizes allows for complete customization. You can easily upload your design and choose the right size with just a few clicks. For guidance on how to get the best results, check out ourDTF transfer instructionsthat walk you through the application process.

Why Choose Ready2Transfer?

Choosing the right supplier for your DTF transfers is crucial, and we pride ourselves on being the best DTF transfer company in the market. Our commitment to quality, speed, and customer satisfaction sets us apart. We offer fast DTF transfer services, with most orders printed and shipped the next day. Our goal is to make your experience seamless and enjoyable, from selecting your transfer to receiving your finished product. Plus, our customer support team is always here to assist you with any questions or concerns.

Get Started Today

Ready to elevate your designs with our DTF Transfers By Size? Explore our collection today and find the perfect fit for your creative projects. With a wide range of sizes and high-quality materials, we make it easy to bring your ideas to life. Don't wait—visit ourDTF transferspage and start your journey towards beautiful, custom prints that leave a lasting impression.

Frequently Asked Questions

What is a DTF transfer by size?

A DTF transfer by size refers to our collection of direct-to-film transfers that are available in various sizes to suit your specific printing needs. Each transfer is designed to be high-quality and ready for application on your chosen garment or material. When you select a size, you're ensuring that your design fits perfectly on your project, whether it's a small t-shirt or a large hoodie. This collection makes it easy to find the right transfer for your unique design.

How do I determine the right size DTF transfer for my project?

To determine the right size DTF transfer for your project, refer to our DTF transfer size chart available on the collection page. The size chart provides dimensions for each transfer option, helping you select the perfect fit for your garment. Additionally, consider the area of the material where you plan to apply the transfer, as well as the design's visibility and impact when choosing the size. If you're unsure, feel free to reach out to our customer service for personalized advice.

Can I customize the design on my DTF transfer by size?

Yes, you can customize the design on your DTF transfer by size! When you place your order, simply upload your unique design, and we'll print it on the transfer film that matches your selected size. This allows you to create personalized items that reflect your style or brand. Our team ensures that your design is printed with precision, resulting in vibrant colors and sharp details that stand out.

How do I apply a DTF transfer from the 'DTF Transfers By Size' collection?

To apply a DTF transfer from our 'DTF Transfers By Size' collection, start by preheating your heat press to the recommended temperature for DTF transfers, usually around 320°F. Place the transfer onto your garment in the desired position, cover it with a protective sheet, and press down for about 10-15 seconds. Allow the transfer to cool slightly before peeling off the film. Following these steps will ensure a professional-looking application that adheres well to the fabric.

What types of materials work best with DTF transfers by size?

DTF transfers from our collection work best on a variety of materials, including cotton, polyester, blends, and even some specialty fabrics. The versatility of DTF transfers allows for high-quality prints on both light and dark materials, making them ideal for t-shirts, hoodies, tote bags, and more. Always make sure to check the fabric's care instructions to ensure compatibility with heat transfer applications for the best results.

What makes the 'DTF Transfers By Size' collection unique?

The 'DTF Transfers By Size' collection is unique because it allows customers to choose transfers that are specifically sized for their projects, ensuring a perfect fit every time. Unlike generic transfers, our collection offers a variety of sizes tailored for different applications, making it easier for you to find exactly what you need. Additionally, each transfer is crafted with high-quality materials, ensuring durability and vibrant colors, setting us apart from other DTF transfer options on the market.

How long does shipping take for DTF transfers by size?

Shipping for DTF transfers from our 'DTF Transfers By Size' collection is typically fast, with most orders printed and shipped the next day. Once your order is placed, you can expect delivery within a few business days, depending on your location. We prioritize quick processing to ensure you receive your custom transfers as soon as possible, so you can start your projects without unnecessary delays.

Can I remove a DTF transfer if I make a mistake?

Yes, you can remove a DTF transfer if needed, but it requires careful handling to avoid damaging the fabric. To remove a transfer, gently heat the area with a heat gun or iron, which will soften the adhesive, allowing you to peel it off slowly. It's important to note that not all fabrics may withstand the removal process, so always test a small area first. If you're unsure, consider consulting our customer service for guidance on the best removal techniques.

What is the difference between DTF transfers and sublimation?

What is the difference between DTF transfers and sublimation?