STEP 1

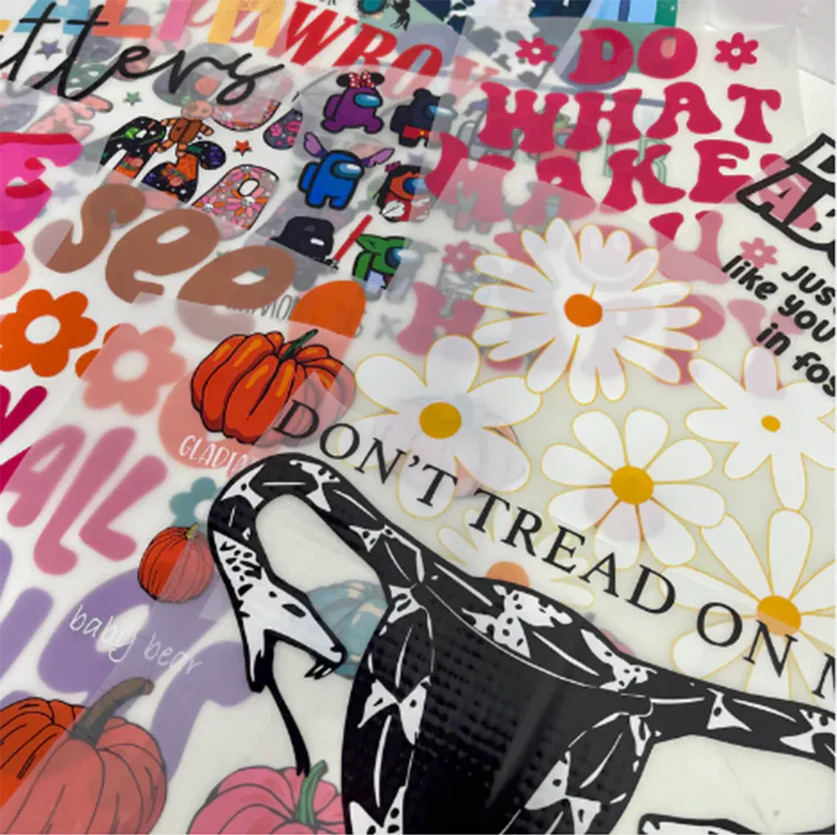

Start by cleaning the application surface thoroughly with isopropyl alcohol or a mild cleaner to remove dust, oils, and debris. Peel the white backing layer away from the UV DTF transfer, being careful not to touch the adhesive side. Position the transfer on your desired location, ensuring proper alignment before making contact.